Hose

At T S Enterprises, our hydraulic hoses are the backbone of fluid power systems. Built to withstand high pressure, extreme temperatures, and demanding conditions, our hoses ensure reliable and efficient performance across various industrial applications.

Our hoses are available in a wide range of sizes, materials, and pressure ratings to meet your specific needs. From standard rubber hoses to specialized thermoplastic and braided steel options, each product is engineered for maximum durability and flexibility. Whether you need a simple replacement or a custom-designed assembly, our hoses are guaranteed to deliver the power and precision your operations demand.

1/4" R2 Hydraulic Hose

The 1/4″ R2 Hydraulic Hose is a high-performance solution designed for demanding applications. Compliant with SAE 100R2 standards, this hose features a two-braid steel wire reinforcement, providing superior strength and pressure resistance. It is engineered to handle higher operating pressures and more rigorous conditions than single-braid hoses, making it ideal for heavy-duty machinery in the earthmoving, construction, and mining industries.

Product details

Material: High-grade synthetic rubber for both tube and cover.

Reinforcement: Multi-layered high-tensile steel wire braid.

Durability: Excellent resistance to abrasion, ozone, and weather.

Standard: Meets or exceeds SAE 100R2 AT standards.

Features: Designed for high pressure, superior flexibility, and long service life.

Specifications

Size: 1/4 inch (6 mm)

Working Pressure: Up to 5,800 PSI (400 bar)

Temperature Range: -40°C to +100°C (-40°F to +212°F)

Fluid Compatibility: Petroleum-based hydraulic fluids, air, and water.

1/4" R1 Hydraulic Hose

Product details

- Material: Durable synthetic rubber for the inner tube and outer cover.

- Reinforcement: Single-braid high-tensile steel wire.

- Versatility: Suitable for a broad spectrum of hydraulic systems.

- Standard: Meets or exceeds SAE 100R1 AT standards.

- Features: A lightweight and flexible design for easy routing and installation.

Specifications

Size: 1/4 inch (6 mm)

Working Pressure: Up to 3,000 PSI (207 bar)

Temperature Range: -40°C to +100°C (-40°F to +212°F)

Fluid Compatibility: Petroleum and water-based hydraulic fluids.

diesel unloading

At T S Enterprises, our Diesel Unloading Hoses are specifically engineered for the safe and efficient transfer of diesel fuel. Designed with durability and safety as paramount, these hoses are crucial for various applications, including fuel delivery, storage facilities, and industrial use. Our diesel unloading hoses are available in various sizes and materials to suit your specific operational requirements. Constructed to resist fuel degradation and external wear, they ensure a reliable and long-lasting solution for your diesel transfer needs. Whether you require a standard length or a custom assembly, our hoses are built to deliver optimal performance and safety.

Product details

Material: High-quality synthetic rubber compounds specifically resistant to diesel fuel and petroleum-based products.

Reinforcement: Robust textile braiding or spiral plies to provide excellent pressure resistance and prevent kinking.

Durability: Exceptional resistance to abrasion, weathering, ozone, and the chemical effects of diesel fuel.

Standard: Manufactured to meet relevant industry safety standards for fuel transfer hoses.

Features: Designed for safe and efficient diesel transfer, excellent flexibility for easy handling, and a long service life.

Specifications

Size: Available in various internal diameters (e.g., 2 inch, 3 inch, 4 inch).

Working Pressure: Up to [Insert Specific PSI/Bar Rating, e.g., 250 PSI (17 bar)].

Temperature Range: Typically -30°C to +80°C (-22°F to +176°F) – Confirm with specific product details.

Fluid Compatibility: Specifically designed for diesel fuel and compatible with other petroleum-based products.

Fly Ash Handling

At T S Enterprises, our Fly Ash Handling Hoses are expertly designed for the safe and efficient pneumatic conveying of abrasive materials like fly ash, cement, and dry bulk powders. Engineered for exceptional wear resistance, these hoses are the ideal solution for demanding applications in power plants, cement factories, and bulk material handling systems. Available in a wide range of sizes and constructions, our hoses are built to withstand the high-velocity, abrasive nature of fly ash, ensuring a long service life and minimal downtime. Whether you need a standard assembly or a specialized solution for a complex system, our fly ash handling hoses deliver reliable performance and durability.

Product details

Material: High-grade, abrasion-resistant synthetic rubber compound for the inner tube.

Reinforcement: High-tensile textile plies or steel wire helix to prevent kinking and maintain shape under vacuum.

Durability: Superior resistance to abrasion, weather, and external damage.

Standard: Meets or exceeds industry standards for abrasive material handling.

Features: Designed for suction and discharge of highly abrasive materials, excellent flexibility, and a high-burst pressure rating.

Specifications

Size: Available in various internal diameters (e.g., 2 inch, 3 inch, 4 inch).

Working Pressure: Up to [Insert Specific PSI/Bar Rating, e.g., 150 PSI (10 bar)].

Temperature Range: Typically -20°C to +80°C (-4°F to +176°F) – Confirm with specific product details.

Fluid Compatibility: Specifically for dry, abrasive media like fly ash, cement, and other powders.

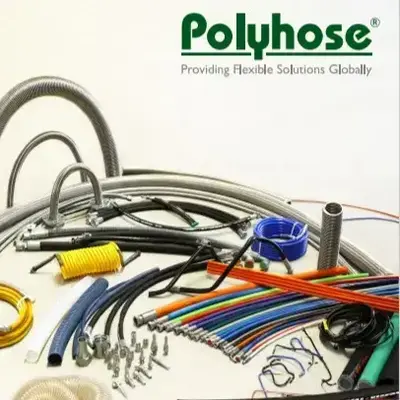

POLYHOSE R1, R2, R4, R5, R6

At T S Enterprises, our Polyhose Series (R1, R2, R4, R5, and R6) represents a comprehensive range of high-performance hydraulic hoses, each designed to meet specific industry standards and application needs. These hoses are engineered to be the workhorses of hydraulic systems, ensuring reliable and efficient fluid power transfer under diverse and demanding conditions. Each hose in the POLYHOSE line is crafted with superior materials and construction to deliver maximum durability, flexibility, and resistance to a wide range of operating pressures and temperatures. From single-braid textile reinforcement (R1) to multi-spiral wire constructions for extreme pressures (R4), our POLYHOSE lineup guarantees a perfect fit for any hydraulic application.

Product details

Material: High-quality synthetic rubber resistant to petroleum-based hydraulic fluids and various other industrial fluids.

Reinforcement:

R1/R2: Single and double steel wire braid.

R4: Four-spiral steel wire reinforcement.

R5: Single textile braid with spiral wire reinforcement.

R6: Single textile braid.

Durability: Excellent resistance to abrasion, ozone, and weathering.

Standard: Compliant with respective SAE and EN standards (e.g., SAE 100R1, SAE 100R2, etc.).

Features: Designed for high pressure and long service life. Different series offer varying degrees of flexibility and pressure ratings.

Specifications

Size: Available in a wide range of internal diameters to suit various applications.

Working Pressure: Varies significantly by series (e.g., R1 for medium pressure, R4 for extremely high pressure).

Temperature Range: Typically -40°C to +100°C (-40°F to +212°F) for standard hoses.

Fluid Compatibility: Compatible with a wide range of hydraulic fluids, including petroleum-based and water-glycol fluids.

Hydraulic Hose Assembly

At T S Enterprises, our Hydraulic Hose Assembly are custom-engineered solutions that combine our high-quality hydraulic hoses with precision-fit couplings and fittings. Unlike standard off-the-shelf components, our assemblies are built to your exact specifications, ensuring a perfect fit and optimal performance for your specific machinery and applications. Each assembly is meticulously crafted to meet rigorous industry standards, guaranteeing a secure, leak-free, and durable connection that can withstand extreme pressures, temperatures, and dynamic conditions.

Product details

Components: Consists of a specified hydraulic hose, crimped with compatible fittings (e.g., JIC, NPT, ORFS, Flange).

Material: High-grade synthetic rubber or thermoplastic hose with carbon steel, stainless steel, or brass fittings.

Durability: Built to withstand abrasion, pressure fluctuations, and severe environmental conditions.

Standard: Assembled to meet or exceed international standards like SAE, EN, and DIN.

Features: Custom-built to exact length and configuration; guaranteed secure and leak-free connections; suitable for high-pressure applications.

Specifications

Size: Custom lengths and various hose internal diameters (e.g., 1/4 inch to 2 inch).

Working Pressure: Varies based on the hose and fitting type used in the assembly.

Temperature Range: Varies based on the hose material.

Fluid Compatibility: Compatible with a wide range of hydraulic fluids, including petroleum-based, water-glycol, and fire-resistant fluids.